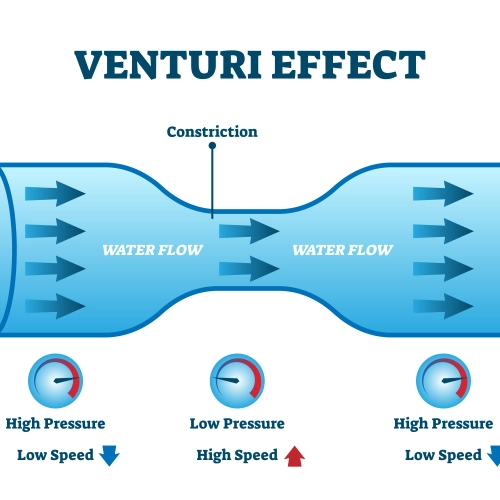

The Venturi effect is a fluid mechanics phenomenon that occurs when a moving fluid passes through a conical-shaped section of tube, narrowing in the central part and then widening again.

This phenomenon was discovered by the Italian physicist Giovanni Battista Venturi at the end of the 18th century and has since been of great importance in various fields of science and engineering.

Functioning

The basic principle behind the Venturi effect is the conservation of energy in a moving fluid. According to Bernoulli's principle, in an ideal frictionless fluid flow, the sum of kinetic energy and potential energy per unit volume is constant throughout a fluid stream. In other words, when the speed of the fluid increases, its pressure decreases, and vice versa.

When a fluid flows through a tapering section of pipe the velocity of the fluid increases in the region where the diameter of the pipe is smaller. This is because the fluid flow must retain its volumetric flow, meaning that the same amount of fluid must pass through any cross section of the tube in a given time. As a result, for faster flow, the cross-sectional area must be smaller.

When a fluid flows through a tapering section of pipe the velocity of the fluid increases in the region where the diameter of the pipe is smaller. This is because the fluid flow must retain its volumetric flow, meaning that the same amount of fluid must pass through any cross section of the tube in a given time. As a result, for faster flow, the cross-sectional area must be smaller.

The acceleration of the fluid in the narrow region of the tube leads to a decrease in pressure in that region, in accordance with Bernoulli's principle. This decrease in pressure is what is known as the low Venturi pressure. On the contrary, in the wider sections of the tube, where the fluid velocity is lower, the pressure is higher.

Applications

The venturi effect has numerous applications in engineering and science due to its implications on fluid flow.

Below is an exhaustive list of examples of applications where the Venturi effect plays an important role in different fields of science:

Nuclear engineering

In a nuclear power plant, the Venturi effect is applied in the reactor coolant circulation systems.

In nuclear reactors, it is used in Venturi tubes to measure the coolant flow, guaranteeing correct circulation and cooling of the core. Additionally, it helps in eliminating steam bubbles, improving the efficiency and safety of the cooling system by avoiding hot spots and maintaining a constant temperature in the reactor.

It is also applied in the steam turbines of a nuclear power plant. In these turbines, high-pressure steam expands and accelerates as it passes through Venturi nozzles, transforming the thermal energy of the steam into kinetic energy. This process maximizes the efficiency of energy conversion, increasing the speed of the steam before it impacts the turbine blades, where the kinetic energy is converted into mechanical energy to generate electricity.

Automotive engineering

One of the most common applications is in the carburetion systems of internal combustion engines.

In a carburetor, air flows through a narrow Venturi tube, where it mixes with fuel before entering the engine's combustion chamber. The pressure reduction in the narrow region of the tube helps suck fuel from the tank into the airflow, allowing a proper mixture for combustion.

Hydraulic engineer

Below we present 3 examples of the application of this effect in engineering:

- Venturi flow meters: These are devices used to measure the speed and flow of a fluid in pipes. By measuring the pressure difference between the wide and narrow section, the fluid velocity and flow rate can be calculated.

- Sprinkler irrigation systems: These systems are designed to control and distribute the flow of water through a network of pipes, providing uniform irrigation to crops. The water is expelled in the form of fine drops, imitating rain, which allows efficient and controlled irrigation.

- Hydraulic ejectors: These are devices that allow mixing liquids and transporting substances in irrigation and water treatment systems. They work using the principle of differential pressure to create a high-velocity flow, allowing the suction and mixing of additional liquids, which

- Hydroelectric power plants: Optimizes water flow in turbines and power generation systems.

- Marine propulsion systems: like the turbines of a hydroelectric plant, it influences the efficiency of ship engines and propulsion systems.

Other apps

In chemical engineering, the Venturi effect is used in various equipment and processes. For example, in laboratory aspirators that are used to create vacuum in laboratory equipment, thus facilitating various chemical operations. It is also used in reagent mixers to achieve a homogeneous mixture of reagents in chemical processes. Additionally, air injectors in reactors benefit from the Venturi effect to improve oxygenation and the efficiency of chemical reactions.

In the medical industry, we see this effect in nebulizers, which are used to deliver medications in aerosol form to patients. Mechanical ventilators also take advantage of this effect to control and regulate airflow in the respiratory systems, ensuring adequate breathing in patients with difficulties.

In the field of aeronautics and aerospace, it is applied in the propulsion nozzles of airplane and rocket engines, controlling the expansion and acceleration of exhaust gases. Likewise, it is used in air flow measurement instruments to measure the speed and pressure of the air around aircraft, contributing to their design and aerodynamic performance.

In environmental engineering, water treatment systems use the Venturi effect for aeration and mixing of water in treatment plants, improving the quality of the processed water. Air cleaning gas ejectors also use this effect to facilitate the removal of contaminants from the air, thereby improving ambient air quality.

In mechanical and process engineering, the Venturi effect is applied in vacuum systems to create vacuum in industrial processes. It is also used in absorption refrigeration systems, improving cooling efficiency without the need for mechanical compressors. Air and gas compressors also use it to optimize compression efficiency. In addition, it appears in wind and water tunnels for aerodynamic and hydrodynamic studies, among others.

In the food industry, the Venturi effect influences milk homogenizing systems, which facilitate the mixing and homogenization of dairy products. It is also used in flavoring injectors, influencing the system for incorporating flavorings and additives into food products.

Finally, in civil engineering, ventilation and air conditioning systems use this physical effect to improve airflow and efficiency of HVAC systems. Cooling towers also use this effect to disperse heat in industrial cooling systems, optimizing their performance and energy efficiency.