Hydraulic systems are a part of industrial engineering that combine power and precision to perform a wide variety of tasks in industry, heavy machinery, transportation, and many other applications.

These systems use incompressible fluids, usually hydraulic oil, to transmit power and control movements using the principles of fluid mechanics. In this article, we will explain what hydraulic systems are, how they work, their applications and advantages.

What is a hydraulic system?

A hydraulic system is a set of interconnected components designed to transmit power through the use of an incompressible fluid, such as hydraulic oil. These systems work following Pascal's principle, which states that a change in pressure applied at one point in an incompressible fluid is transmitted without loss to all points in the fluid and to the container walls.

In other words, when a force is applied to a point in the system, this force is transmitted uniformly through the fluid, allowing for precise and powerful mechanical work.

Key components of a hydraulic system

Hydraulic systems consist of several essential components that work together to achieve power transmission and motion control. Some of the key components include:

1. Hydraulic pump

The pump is the system's power source and generates a constant flow of high-pressure hydraulic oil.

2. Hydraulic fluids

Hydraulic oil acts as the working medium in the system. It is incompressible and efficiently transmits energy.

3. Hydraulic actuators

These devices convert hydraulic energy into mechanical motion. Hydraulic cylinders and hydraulic motors are common examples of actuators.

4. Valves

Valves control fluid flow and direction in the system. There are flow control and directional valves that determine where the fluid will move and how much it will flow.

5. Reservoir

The reservoir stores the hydraulic oil and allows for the removal of air and thermal expansion of the fluid.

6. Pipes and hoses

These components connect all the elements of the system and allow oil to flow between them.

7. Control devices

Hydraulic systems often incorporate electronic or manual control devices to regulate and monitor system operation, such as pressure sensors, programmable logic controllers (PLCs), pressure switches, and control panels.

Operation of a hydraulic system

The operation of a hydraulic system is relatively simple but highly efficient. Here is a step by step description of how it works:

-

Pressure Generation: The hydraulic pump takes hydraulic oil from the reservoir and compresses it, generating significant pressure.

-

Flow Control: Valves in the system control the flow of oil, determining the direction and amount of movement. This is accomplished by opening or closing the valves based on the needs of the system.

-

Power transmission: The high pressure generated by the pump is transmitted through the oil to hydraulic actuators such as cylinders or motors. When a valve is opened, oil flows into the actuator, applying a force or creating movement.

-

Carrying out work: Actuators transform hydraulic energy into mechanical work. For example, a hydraulic cylinder can move a load or lift an object, while a hydraulic motor can turn a machine.

-

Precision Control: Hydraulic systems allow precise control of movement. Oil flow and pressure can be precisely adjusted for smooth, controlled movements.

Hydraulic system applications

Hydraulic systems are used in a wide range of applications in various industries. Some notable examples include:

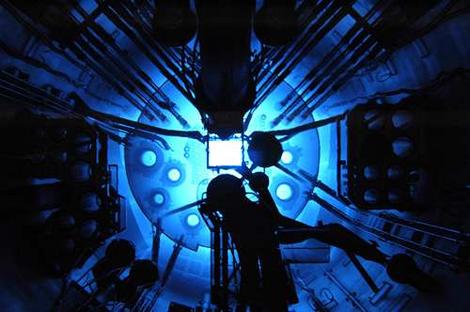

nuclear power plants

Hydraulic systems play an important role in nuclear power plants, where they are used for a variety of functions essential to the safe and efficient operation of these facilities.

Hydraulic systems play an important role in nuclear power plants, where they are used for a variety of functions essential to the safe and efficient operation of these facilities.

Here are some of the hydraulic systems used in nuclear power plants:

-

Control of valves and actuators: This includes the opening and closing of safety valves, coolant flow control valves, and other devices necessary to regulate the flow of water and control the temperature and pressure in the reactor core.

-

Cooling systems: help circulate and control the flow of water in cooling systems.

-

Lifting and handling of equipment: In nuclear power plants, it is essential to be able to move and lift heavy components or equipment within the plant. The operation of cranes, manipulators and elevators to carry out these tasks work through these systems.

-

Safety Systems: Hydraulic systems are used in critical safety systems, such as control rods. These rods, which are inserted into the reactor core to regulate the nuclear reaction, are often hydraulically operated for quick and accurate response in an emergency.

-

Pump and compressor control: Nuclear power plants require a wide range of pumps and compressors to circulate water, gases, and other fluids in the system. Hydraulic systems can be used to control these pumps and compressors.

Manufacturing industry

In industrial production, hydraulic systems control presses, stamping machines, and other equipment that requires force and precision.

Aeronautics

Hydraulic systems are used in aircraft to operate landing gear, flaps, and braking systems.

Vehicles

Braking and steering systems on heavy vehicles, such as trucks and buses, are often hydraulic.

Elevators and hoists

Hydraulic systems provide smooth, controlled movement in elevators and hoists.

Heavy machinery

Excavators, cranes, bulldozers, and other heavy equipment use hydraulic systems to dig, lift, and move large loads.

Advantages of hydraulic systems

Hydraulic systems offer several significant advantages:

-

Power and control: Hydraulic systems can generate a large amount of force and allow precise control of movement, making them ideal for applications that require both qualities.

-

Compact and Efficient: Hydraulic components are relatively compact compared to other power transmission systems, allowing for efficient design and high performance.

-

Durability: Hydraulic systems are known for their durability and ability to withstand heavy loads and severe conditions.

-

Quick response: Hydraulic systems can respond quickly to changes in power demand, making them suitable for dynamic applications.

-

Wide Temperature Range – Hydraulic oil is capable of operating effectively over a wide range of temperatures, making it suitable for applications in a variety of environments.