A hydraulic power press is a simple machine that allows a small force to be multiplied thanks to the Blaise-Pascal principle. This type of machine is an example of fluid mechanics used in various industries, especially the automotive industry, to manage heavy-duty tasks.

These types of presses are the most used, but there are also other types of presses, such as mechanical, pneumatic, and screw presses.

In this article, you will discover a hydraulic press and how it works to move large objects.

What is the hydraulic press?

A hydraulic press is the most straightforward hydraulic machine designed to obtain significant compressive forces based on Pascal's law. Formerly called the "Brahm press," it was invented and patented by Joseph Bramah in 1795.

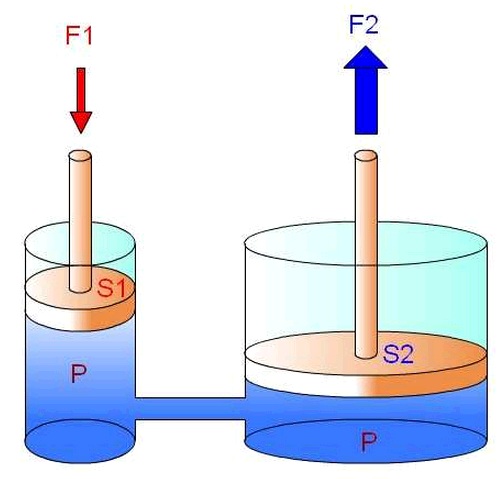

This machine consists of two communicating vessels driven by two pistons of different areas. It is based on the Pascal principle, allowing a relatively small force to amplify the piston. When force is applied to a piston with a smaller area, it generates a greater force on a piston with a larger area.

How does the hydraulic press work?

This hydraulic machine works based on Pascal's principle. These are two pistons from two different areas connected through a fluid. This fluid transmits the forces from one side to the other and can be water or some special hydraulic oil.

The fluid in a container maintains the same relationship between force and pressure at all points in the liquid. This property is explained by Pascal's law, in which the relationship F1/S1 = F2/S2 is maintained.

The fluid in a container maintains the same relationship between force and pressure at all points in the liquid. This property is explained by Pascal's law, in which the relationship F1/S1 = F2/S2 is maintained.

Thus, a small force applied to the small area piston exerts pressure transmitted to the large piston. However, this time, because the area is larger, it exerts a greater force to maintain the same ratio.

Water pistons maintain a certain similarity to the law of the lever because both systems allow a force to be multiplied at a lower cost. However, the mechanism by which this phenomenon occurs is different.

Uses of hydraulic press machine

Hydraulic presses are mainly used in industrial applications. A vast range of hydraulic presses can be used in many sectors and daily lives.

Here are some examples of uses and applications:

Here are some examples of uses and applications:

-

Uses in industry and component manufacturing: These types of presses are used above all for the vertical compression of parts of various sizes and product details. These types of presses are used to assemble electronic parts and components. For example, a frame hydraulic press is helpful for shaping steel plates with the help of a die or for cutting parts through dies. Usually, they are hand-operated devices, and the frame is fabricated from cast iron.

-

Automotive: In the automotive industry, the hydraulic press system is used for manufacturing and operation. Some examples are the brakes' operation to engage and disengage an engine, assembling shock absorbers, manufacturing steel-fabricated panels, etc. These machines are much more complicated and usually have a control panel to manage an electric motor that exerts force.

-

Food: Presses compress food, for example, during packaging or cheese making.