The Venturi tube is a fundamental device in fluid mechanics, used to measure the velocity of a fluid or its flow rate.

It was invented by Italian physicist Giovanni Battista Venturi in the 18th century and works based on Bernoulli's principle , which describes how the pressure of a fluid decreases as its velocity increases in a region of restricted flow. This phenomenon is key in many practical applications that take advantage of fluid properties, such as in aeronautical engineering, flow measurement, and pumping systems.

How the Venturi tube works

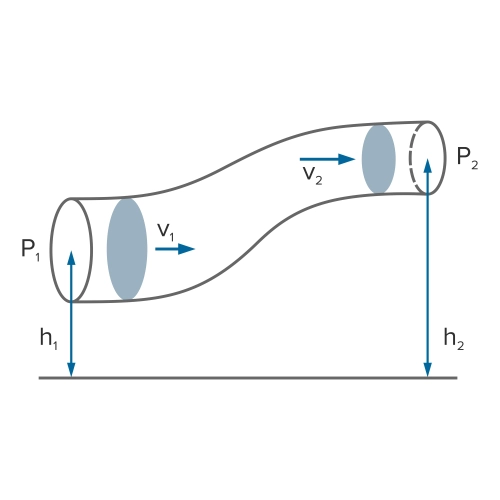

A Venturi tube consists of three main sections:

- Wide section inlet : Here, the fluid enters the tube at a relatively low velocity and with a higher pressure.

- Narrow section or throat : The diameter of the pipe is considerably reduced in this part, which causes an increase in the speed of the fluid due to the conservation of mass (principle of continuity). Consequently, the pressure decreases.

- Wide section exit : Upon exiting the narrow section, the tube widens again, allowing the fluid velocity to decrease and the pressure to increase again.

This simple design allows the flow of a fluid to be measured through the pressure difference between the wide section and the throat. According to Bernoulli's equation, in an incompressible flow, the total energy remains constant, so as the velocity of the fluid in the throat increases, the pressure must decrease proportionally.

Bernoulli's principle applied to the Venturi tube

The relationship between pressure and velocity in the Venturi tube can be understood through Bernoulli's equation . This equation states that for an incompressible, frictionless fluid, the sum of kinetic energy (related to velocity), potential energy (related to height), and pressure at any point in the flow is constant.

The relationship between pressure and velocity in the Venturi tube can be understood through Bernoulli's equation . This equation states that for an incompressible, frictionless fluid, the sum of kinetic energy (related to velocity), potential energy (related to height), and pressure at any point in the flow is constant.

In the Venturi tube, the height contribution is usually ignored because the height differences between the different sections of the tube are usually negligible.

The equation is therefore simplified, focusing on the relationship between pressure and velocity. When the pipe diameter is reduced at the throat, the fluid velocity must increase to maintain the flow rate. This increase in velocity causes a decrease in pressure, according to Bernoulli's principle.

Examples of applications of the Venturi tube

The Venturi tube is used in a wide range of applications in engineering and other fields, due to its ability to accurately measure the flow rate of a fluid and the properties related to its pressure and velocity. Some of the most common applications include:

1. Flow measurement in fluid systems

The Venturi tube is often used as a flow meter , as it allows the flow of a fluid to be calculated by measuring the pressure difference between the wide section and the throat.

The Venturi tube is often used as a flow meter , as it allows the flow of a fluid to be calculated by measuring the pressure difference between the wide section and the throat.

This type of measurement is used in industrial applications, irrigation systems, water treatment plants and many other areas where it is necessary to control the flow of liquids or gases. Venturi meters are highly accurate and efficient, as they cause less energy loss compared to other flow measurement devices.

2. Applications in internal combustion engines

The Venturi effect is used in internal combustion engine carburettors to mix air and fuel in proper proportions before combustion.

Air entering the carburetor passes through a narrow throat, which increases its velocity and reduces its pressure. This pressure drop creates a suction that draws in the fuel in vapor form, mixing it with the air before it enters the combustion chamber.

3. Ventilation and cooling systems

In cooling and ventilation systems, the Venturi tube is used to control the flow of air and coolant. By taking advantage of Bernoulli's principle, these systems can efficiently adjust fluid velocity and pressure, improving energy efficiency and ensuring uniform distribution of coolant or air.

4. Injectors and pumping systems

The Venturi principle is also used in injectors , which are devices designed to mix liquids or gases by means of suction created by decreasing pressure.

Injectors are used in a variety of applications, from medical equipment to irrigation systems and industrial pumping stations. In these systems, the pressure drop across the throat of the Venturi tube is harnessed to create a suction force that draws fluid from a secondary source and mixes it with the primary fluid.

5. Aircraft and aerodynamics

In aeronautical engineering, the Venturi tube helps explain how airplanes generate lift.

In aeronautical engineering, the Venturi tube helps explain how airplanes generate lift.

The aerodynamic profile of an airplane wing creates a Venturi effect: the air passing over the top of the wing moves at a higher speed and therefore experiences lower pressure than the air passing below it.

This pressure difference generates a lift force that allows the plane to rise.