Yield strength is a fundamental property in materials science and engineering that defines the ability of a solid material to withstand stresses without undergoing permanent deformation.

This property is essential for the design and manufacturing of a wide variety of products, from building structures to automotive components and electronic devices.

What is elastic limit?

The yield point is the point on a stress-strain diagram at which a material stops behaving elastically and begins to deform plastically when a load or force is applied to it.

To understand this definition, it is important to understand the concepts of elastic deformation and plastic deformation.

Elastic Deformation: When a force is applied to a solid material, it initially deforms elastically, meaning it returns to its original shape once the force is removed. In this phase, atomic and molecular interactions in the material allow it to recover its original shape.

Plastic deformation: When the applied force exceeds the elastic limit of the material, the deformation becomes permanent, and the material undergoes plastic deformation. In other words, the material no longer returns to its original shape after the load is removed. This can result in irreversible changes in the shape and properties of the material.

Elastic limit measurement

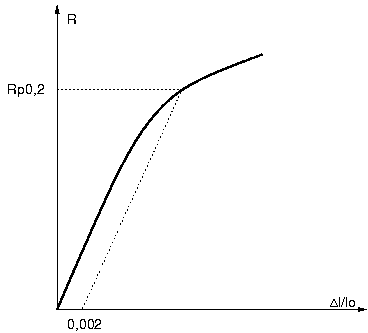

The yield strength is determined by tensile testing, which involves gradually applying a load to a material while measuring the resulting deformation. The results are represented in a stress-strain diagram, which shows stress on the vertical axis and strain on the horizontal axis.

The yield strength is determined by tensile testing, which involves gradually applying a load to a material while measuring the resulting deformation. The results are represented in a stress-strain diagram, which shows stress on the vertical axis and strain on the horizontal axis.

The following describes how the yield strength is determined on a stress-strain diagram:

Initial elasticity : In the initial part of the curve, the relationship between stress and strain is linear, meaning that the material deforms elastically. The slope of this initial line is known as Young's modulus and provides information about the stiffness of the material.

Yield point : The yield point is located at the point where the stress-strain curve begins to deviate from the initial straight line. At this point, the material begins to show signs of plastic deformation. The stress value at this point is the elastic limit of the material.

Plastic deformation : After passing the elastic limit, any further deformation will result in plastic deformation, and the material will not return to its original shape upon removal of the load.

Importance in materials engineering

Yield strength is a critical property in the design and selection of materials for specific applications.

Some examples of its importance are the following:

1. Structure design

In the construction of buildings, bridges and other structures, it is essential that the materials used have an adequate yield strength to resist the expected stresses. If a material has an insufficient yield strength, the structure could deform or collapse under service loads.

2. Manufacturing of components

In the manufacturing industry, such as automobile, aircraft, and machinery manufacturing, components must maintain their form and function throughout their useful life. Knowledge of the yield strength is crucial to selecting materials that can withstand the expected stresses and deformations without premature failure.

3. Design of electronic devices

In electronics, materials used in devices such as integrated circuits and cables must have adequate elastic limits to avoid deformations that could affect their performance or durability.

4. Design of nuclear power plants

In the design of a nuclear power plant there are several critical components such as nuclear fuel rod cladding or coolant pipes. Any permanent deformation of these elements could compromise the safety and efficiency of the plant.

These elements include the nuclear reactor vessel, piping and fittings, fuel rod casings, containment vessels, steam generators, turbines, pumps, support structures, radiation shields, nuclear waste storage systems, and more.

Ensuring that materials used in the nuclear industry have an adequate yield strength is essential to prevent radioactive leaks, component breakage, and potential nuclear incidents. Additionally, materials must be able to withstand repeated thermal loading and unloading cycles without undergoing plastic deformation, contributing to the long-term service life and reliability of nuclear facilities.

Tables with examples of elastic limits of materials

Below, I present a table with common materials in various fields, along with a brief description of their uses and their typical elastic limits:

Material | Description | Elastic limit (Approximate) |

Carbon Steel | Widely used in construction and automotive industry | 250MPa |

Aluminum | Light and resistant, it is used in aeronautics, packaging and construction | 110-400MPa |

Copper | Excellent electrical conductor, used in cables and electronics | 100-220MPa |

High density polyethylene | Common in pipes and containers | 20-35MPa |

Glass | Used in windows, packaging and optical applications | 30-60MPa |

Pinewood | Widely used in construction and carpentry | 30-60MPa |

Polypropylene | Versatile and corrosion resistant, common in packaging and components | 25-45MPa |

What does the elastic limit of a material depend on?

The yield strength of a material depends on several factors, and its value can vary significantly from one material to another. Some of the main factors that influence the elastic limit of a material are:

- Chemical composition : Different chemical elements, alloys can have different elastic properties.

- Crystalline structure : The internal structure of the material, especially its crystalline structure, affects the elastic limit. The arrangement of atoms and the interatomic bonds that form molecules plays a key role in the resistance of the material.

- Heat Treatments : Heat treatments, such as quenching and tempering, can modify the elastic properties of a material by changing its internal structure.

- Processing and manufacturing : The manufacturing process and processing conditions can influence the yield strength. Cold deformation, for example, can increase the strength of the material.

- Temperature : Some materials can become more brittle at low temperatures, while others can maintain their elasticity at extremely high temperatures.

- Loading conditions : The conditions under which the load is applied to the material are also important. The speed of loading, direction of force, and duration of loading can affect the elastic response of the material.

- Presence of defects : The presence of defects in the material, such as cracks or inclusions, can weaken the elastic limit and reduce the strength of the material.