A pressurized water reactor (PWR) is a type of nuclear reactor where the water used in the primary circuit is kept under high pressure to prevent it from boiling.

In the absence of this high pressure, the heat inside the reactor could easily turn the water into steam, disrupting the process. PWRs are widely used in nuclear power plants around the world to generate electricity, with over 230 reactors currently in operation.

The original purpose of the PWR model was for use in nuclear submarines, where space constraints and safety were critical factors. Over time, the design proved to be effective for electricity generation, and it is now the most common type of reactor in use globally, alongside boiling water reactors (BWR). Both PWR and BWR are classified as light water reactors because they use ordinary water as both a coolant and a neutron moderator.

Advantages of Pressurized Water Reactors (PWR)

-

Stability and Safety: One of the most significant advantages of PWRs is their inherent stability. The reactor has a natural tendency to reduce power output when the temperature increases, a feature known as negative temperature coefficient. This reduces the likelihood of overheating and enhances safety.

-

Low Fuel Requirements: PWRs can operate with less fissile material compared to reactors that operate under critical conditions. This decreases the risk of uncontrolled power surges, making them safer.

-

Use of Ordinary Water: PWRs use ordinary water (also called light water) as a neutron moderator, which is readily available and cheaper than heavy water, which some reactors require. This reduces the overall operational costs.

-

Proven Technology: With more than 230 reactors globally, the PWR has a long track record of proven performance in electricity generation.

-

Efficient Heat Exchange: The separation of the primary and secondary circuits ensures that radioactive water does not come into contact with the steam, minimizing contamination risk.

Disadvantages of Pressurized Water Reactors (PWR)

-

High-Pressure Requirement: The primary coolant water must be maintained at high pressure (around 16 megapascals) to keep it from boiling. This requires the use of large, expensive pressure vessels and increases construction costs. It also presents a higher risk of accidents, particularly if there is a loss of coolant.

-

Limited Fuel Reprocessing: PWRs cannot change spent fuel while in operation. This necessitates periodic shutdowns for fuel replacement, which can lead to downtime and added operational costs.

-

Corrosion Issues: The water in the primary circuit, which contains dissolved boric acid, is corrosive to stainless steel. This corrosion can lead to the circulation of radioactive corrosion products in the primary circuit, which limits the reactor’s useful life and requires additional filtering systems.

-

Fuel Costs: Since ordinary water is less effective as a neutron moderator compared to heavy water, PWRs require enriched uranium as fuel. This increases fuel costs compared to reactors using natural uranium or heavy water.

-

Inability to Use Fast Neutrons: The use of water as a neutron moderator makes it impossible to design a fast reactor using a PWR layout. Fast reactors are designed to use fast neutrons to drive fission reactions, which requires a different type of moderator or no moderator at all.

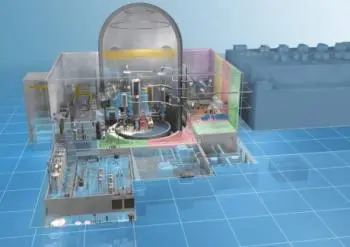

How do pressurized water reactors work?

The functioning of a PWR is based on a four-step cycle:

The functioning of a PWR is based on a four-step cycle:

-

Fission and Heat Generation: The reactor core, housed in the reactor vessel, generates heat through nuclear fission reactions, where uranium atoms split and release large amounts of energy.

-

Primary Circuit Heat Transfer: Water in the primary circuit absorbs this thermal energy. The high pressure prevents it from boiling, ensuring it remains in liquid form despite high temperatures.

-

Secondary Circuit Steam Generation: The heated water from the primary circuit flows to a steam generator. Here, it transfers its heat to the water in a secondary circuit, turning it into steam.

-

Electricity Production: The steam drives a turbine, which is connected to an electricity generator. As the turbine spins, electricity is produced.

After the steam has passed through the turbine, it enters a condenser, where it is cooled and converted back into liquid form. This liquid water then flows back to the steam generator to begin the cycle again. The condenser typically cools the steam using a tertiary circuit of cold water, such as seawater or river water.

The Reactor Core and Nuclear Reactions

The reactor core contains nuclear fuel rods, typically made of enriched uranium, which undergo fission when bombarded by neutrons. Each fission event releases thermal energy and produces additional neutrons that continue the reaction chain.

To ensure safety, PWRs are designed to operate within a specified temperature range, as exceeding this could cause the fuel rods to melt. The coolant system, driven by reactor coolant pumps, circulates water through the core to absorb and transport this heat.

In PWR reactors, the primary circuit water is kept separate from the secondary circuit to prevent contamination. The water in the primary circuit is radioactive, while the secondary water that generates steam is not. This separation is crucial for maintaining safety and preventing the release of radiation.

Coolant and Moderator in PWR

The primary coolant in a PWR is light water, which remains in a liquid phase even at temperatures as high as 315°C, due to the high pressure. This water is essential for maintaining the appropriate temperature within the reactor core and transferring heat to the secondary circuit.

Water also serves as a neutron moderator in PWRs. In a nuclear reactor, fast neutrons produced during fission are slowed down by the moderator, which allows further fission reactions to occur. Since water is effective at slowing neutrons, it plays a key role in sustaining the chain reaction in PWR reactors.

Control of Nuclear Reactions

To control the fission process, control rods made of neutron-absorbing materials are inserted or withdrawn from the reactor core. When inserted deeply, the control rods absorb more neutrons, reducing the number of fission reactions and lowering the power output. Conversely, withdrawing the rods increases the number of neutrons available for fission, raising the reactor's power.