A boiling water reactor (BWR ) is a type of nuclear reactor widely used in nuclear power plants around the world, being the second most common after the pressurized water reactor (PWR). It accounts for approximately 22% of the reactors installed in nuclear power plants worldwide.

Designed primarily for electricity generation, the BWR uses light water as both a neutron moderator and core coolant. One of its particularities is that it operates with a single water circuit, in contrast to PWR reactors, which require separate primary and secondary circuits.

Furthermore, because it operates at lower pressures, the BWR does not require as robust a casing as the PWR, which simplifies some aspects of its design. However, unlike the PWR, the BWR does not have a steam generator, which influences its configuration and operation.

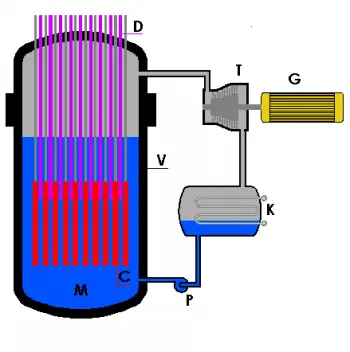

Schematic diagram of the operation of a boiling water reactor

The power of the boiling water reactor is generated in the reactor core. In the reactor core, nuclear fission reactions of the fuel element are generated to obtain thermal energy.

The reactor power is regulated by inserting or removing control rods from the core, where nuclear chain reactions occur.

In the BWR reactor, the water used is light water (regular water). This type of nuclear reactor uses a single cooling circuit. The light water circulates through the core where it captures the heat from nuclear reactions until it reaches boiling point and steam is generated.

Steam generated in the reactor core exits at the top. At this point, steam dryers and water separators treat the steam leaving the reactor. It is then directed directly to the turbines.

The turbines will be responsible for operating the electric generator and generating electricity.

Finally, the steam passes through a condenser to convert it into liquid water again and start the cycle again.

The boiling water reactor uses a single cooling circuit, so the steam that drives the turbine is made up of water that has passed through the interior of the reactor. For this reason, the turbine building must be protected to avoid radioactive emissions.

Main features of a reactor (BWR)

Direct steam generation

Unlike other types of reactors, such as the pressurized water reactor (PWR), in the BWR the water is heated directly inside the reactor core until it reaches its boiling point. This means that the steam that drives the turbines to generate electricity comes directly from inside the reactor.

This design eliminates the need for a secondary circuit, simplifying heat transfer.

Using water as a coolant and moderator

The reactor uses light water (H₂O) for two essential functions:

- Coolant: Absorbs heat generated during nuclear fission.

- Moderator: Reduces the speed of neutrons, allowing them to be more effective in causing new fissions.

This ensures that the chain reaction is sustainable and controlled.

Relatively low operating pressure

Water boils inside the reactor at a lower pressure than in other reactors such as the PWR. This translates into safer operating conditions and lower demands on construction materials.

Direct interaction of steam with turbines

The steam generated in the core travels through a circuit directly to the turbines. There, its kinetic energy is transformed into mechanical energy and then into electrical energy by a generator.

Since there is no intermediate heat exchange, the system has less energy losses.

Power control system

The reactor power is regulated by:

- The movement of the control rods, which absorb neutrons to slow the chain reaction.

- Adjusting the flow of water through the core, which affects the amount of steam produced.

- This system allows for rapid and precise regulation of the energy generated.

Radioactive contamination in the primary circuit

Since the steam comes directly from the reactor core, it may contain small amounts of radioactive material. For this reason, the entire circuit carrying the steam must be carefully shielded and monitored.

Advanced security design

Although BWRs are simpler in design than other reactors, they include multiple safety systems, such as emergency cooling systems, primary and secondary containment to prevent the release of radioactive materials.

Advantages and disadvantages of boiling water reactor

Compared to other types of powertrains, BWRs have the following strengths and weaknesses:

Advantages

- The nuclear fuel used by the nuclear reactor is uranium oxides enriched between 2% and 4%.

- The boiling water reactor does not use steam generators or pressure compensators.

- The first reactor circuit operates at a pressure of 70 atmospheres compared to 160 atmospheres used by PWR reactors (pressurized water reactor).

- Requires lower operating temperatures, even in the fuel rods.

- Due to the rejection of neutron absorption in boron and a slightly weaker neutron moderation (due to steam), the operating time of plutonium in such a reactor will be longer than in the PWR.

- The pressure vessel is subjected to less irradiation than in a pressurized water reactor. For this reason, it does not become as brittle with age.

Disadvantages

- Impossibility of reloading nuclear fuel without stopping the nuclear reactor.

- More complicated management.

- The control rods must be introduced from below. In the event of a power loss, they would not be able to fall into the reactor due to gravity and the reactor would not be shut down.

- Need for more feedback sensors.

- A reactor vessel approximately 2 times larger in volume than a PWR of comparable power is required.

- Although it is designed for lower pressure, it is more difficult to manufacture and transport.

- Turbine contamination with water activation products: short-lived N-17 and traces of tritium. This makes maintenance work considerably more complicated.

- Once the control rods are fully inserted, the reaction stops. However, the nuclear fuel continues to emit heat. This means that once the reactor is shut down, coolant must continue to be pumped in for one to three years to keep it safe.

Featured Examples

Some prominent examples of boiling water nuclear reactors (BWR) include:

1. Fukushima Daiichi Nuclear Power Plant (Japan)

The Fukushima Daiichi plant, infamous for the 2011 nuclear accident, used BWR reactors designed by General Electric. It was one of Japan's largest nuclear facilities before the disaster, with six BWR reactors in operation.

This plant had six operational BWR reactors: reactor power was 460 MW, while the average power of reactors 2-6 was between 784 and 1,100 MW.

2. Browns Ferry Nuclear Power Plant (United States)

Located in Alabama, this plant is one of the largest nuclear power plants in the world in terms of generating capacity and operates three BWR reactors. These reactors were also built by General Electric.

This plant has 3 reactors:

- Reactor 1: 1,065 MW, operating since 1974.

- Reactor 2: 1,113 MW, operating since 1975.

- Reactor 3: 1,113 MW, operating since 1977

3. Oskarshamn Nuclear Power Plant (Sweden)

The Oskarshamn power plant houses one of the largest BWR reactors in the world in terms of generating capacity, designed to supply power to Sweden and its surrounding areas.

4. Laguna Verde Nuclear Power Plant (Mexico)

It is the only nuclear power plant in Mexico, located in the state of Veracruz, and operates two BWR reactors. It contributes significantly to the generation of electric energy in the country.

5. Kashiwazaki-Kariwa Nuclear Power Plant (Japan)

Considered one of the largest nuclear power plants in the world, Kashiwazaki-Kariwa has seven reactors, some of which are BWR type and others are ABWR (advanced boiling water reactors).